High-pressure water mist

Effective fire suppression system for industrial mobile equipment

The FOGMAKER fire suppression system is developed and manufactured in Sweden.

FOGMAKER has a successful global track record in Europe, Australia, North and South America, Middle East & Africa– with over 270,000 units installed worldwide since 1995.

WHY FOGMAKER?

We serve to save lives and valuable vehicles

Always active – no power supply needed

Outstanding choking and cooling technology

Cost-effective and tailored retrofitting

Modular design for installation options

SEE FOR YOURSELF

FOGMAKER in action

Live demo of FOGMAKER fire suppression system.

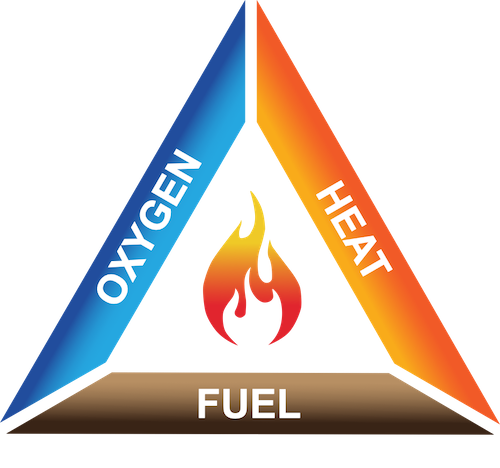

TRIPLE ACTION

FOGMAKER fire suppression systems effectively attack all three sides of the fire triangle

A fire requires three elements to sustain combustion – oxygen, heat and fuel. Removing one of these elements from the environment will extinguish the fire. The majority of fire suppression system’s approach is to remove oxygen from the fire zone and thus suffocate the fire. However, this is often a temporary situation: as air and oxygen return to the fire zone, with the presence of the all three elements, the fire often re-ignites.

INSTALLATION

Where should you use the FOGMAKER system?

In industries where the consequential damages from a fire on your valuable asset is high, with the possible loss of life or damage to the environment, the installation of FOGMAKER’s reliable and effective automatic fire suppression system should be considered as part of your fire mitigation strategy.

FOGMAKER fire suppression system (FSS) is suitable for:

Mining and Tunneling

Forestry

Marine

Buses and Coaches

Gensets

Are your valued assets really protected from the threat of fire?

An automatic fire suppression system is recommended for all engine compartments and enclosed spaces!

Mining Vehicles

Buses & Trucks

Military Vehicles

SOLUTIONS

Is the FOGMAKER system best suited for you?

Get in touch with us and our team will advise on a cost-effective and reliable solution for your industry and valuable assets.